The solar modules lifetime is limited about 25 years before they have to be recycled. So for many of the panels that were produced in the 1980s and 90s this time has come. But how to properly recycle the solar panel ?

How to recycle waste solar photovoltaic panels for profit? With the large-scale production of the global solar energy manufacturing industry in the past few years, a few years later, the world will set off a wave of "scrappy" photovoltaic panels, which will even reach tens of millions of tons by 2050!

How to deal with and recycle waste photovoltaic panels has become an important issue. Previously aged or damaged solar panels are usually sent to glass recycling facilities, and only glass and aluminum frames are recycled. The remaining materials will be sent to the cement furnace for incineration, resulting in environmental pollution and waste of resources.

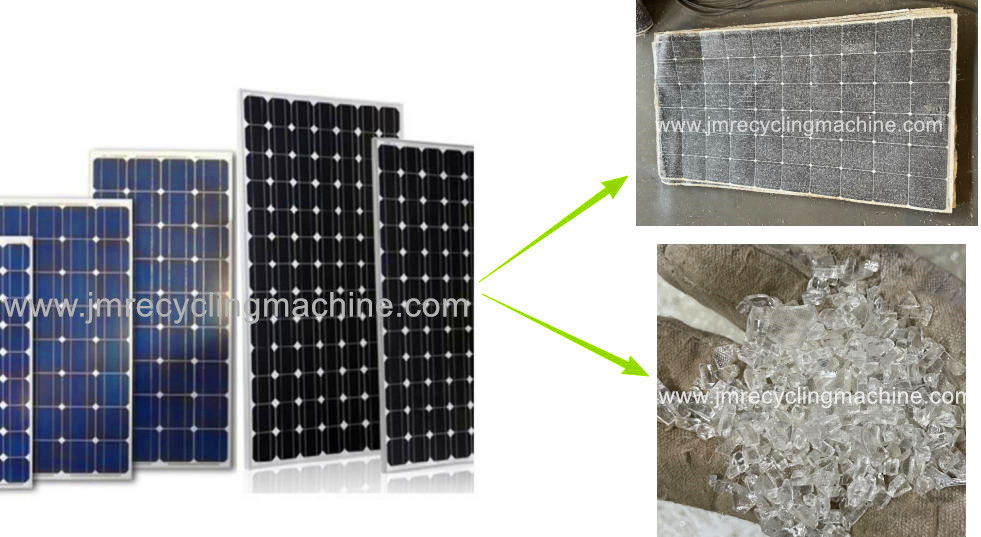

Solar panel recycling and processing equipment has broken the difficult problem of photovoltaic panel recycling and processing, and is of great significance to linear resource recycling and environmental protection. "Photovoltaic panels. A typical crystalline silicon solar panel is made of 65-75% glass, 10-15% aluminum frame, 10% plastic and 3-5% silicon. The photovoltaic panel recycling and processing equipment produced can disassemble, sort, process and recycle 95% of its materials. After sorting and packaging, the sorted materials are sent to different industries for reuse. Two-thirds of glass is recycled as cullet and sent to glass manufacturing; aluminum frames are sent to aluminum refineries; waste plastics can be used as fuel in cement plants; recycled silicon can be reused in the precious metals industry Utilize; the remaining cables and connectors are crushed and sold as copper beads. This series of models is mainly used for scrapped silicon-based thin-film cells, photovoltaic films, thin-film solar cells, etc. It can crush the bottom film and silicon wafer together, and automatically separate the film and silicon crystal material after crushing, with a cleanliness of 90-99 %. Greatly improve the recycling value of photovoltaic panels. Contact me get full project of the machine.

Solar panel are composed of photovoltaic(PV) cells that convert sunlight to electricity, when these panels enter landfills, valuable resource go to waste. And because solar panels contain toxic materials like lead that can lead out as they break down, landfill also creates new environmental hazards.

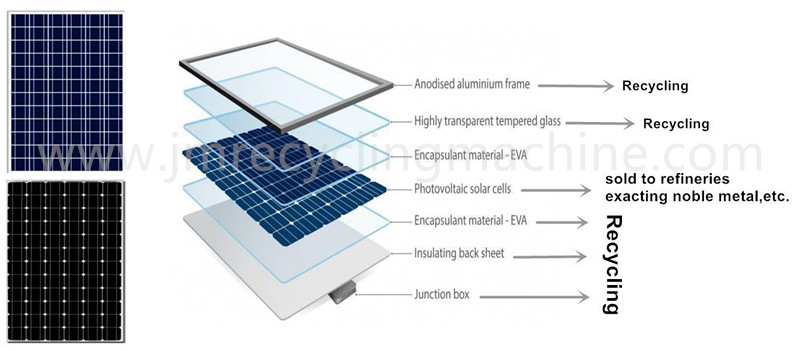

The main components of photovoltaic modules are Aluminum Frame,tempered glass,Solar cell, EVA and Back sheet. Among them, the main component of glass is silica, secondary components are soda, limestone, magnesium oxide,alumina, mirabilite,carbon.EVA Encapsulant is mainly ethylene-EVA ethylene copolymer.The core components of solar cell are mainly monocrystalline silicon and polycrystalline silicon. The main material of the frame is aluminum. The back sheet is composed of two-layers PVF films and one-layer PET film. More than 90 percent of these materials can be recycled.

Recycling process

For silicon PV modules, the recycling process consists of multiple steps. After removing the (mostly) aluminium frames and the junction boxes with cables, the rest of the module - including glass, backsheet and solar cells - are then crushed in small pieces (<5mm).

Then the fractions are separated and sorted according to material type, at the latter the glass is separated from the EVA pieces. The digested and separated raw materials (mainly glass, foil and aluminum) now meet the requirements for further processing with regards to particle size and separation of the compounds.

The metal parts are precipitated in a three-stage process by increasing pH using sodium hydroxide. Up to 90% of a module's glass and 95% of the semiconductor material can be recovered during this process. Waste of the aluminium frames for example can be recycled and processed into usable raw material for furniture, cell phones or again solar panel frames. The silicon cells can be re-cycled as raw material for new solar cells

As for non-silicon PV modules, such as thin-film modules, these basically need to undergo chemical treatment in order to separate the various semiconductor materials, which in best case allows up to 95% recovery of the material parts.The final products are aluminum frame,Glass,Metal,Silicon power,Plastic.